Explore

10 colors available

8 colors available

10 colors available

8 colors available

2 colors available

4 colors available

10 colors available

10 colors available

11 colors available

4 colors available

6 colors available

2 colors available

1 color available

7 colors available

1 color available

1 color available

1 color available

Discover our

Products

OUR STORY

Carmel's mission: Inspire and support professionals worldwide with high-quality writing instruments and specialty waxes.

Wholesale Inquiries

Seeking Large Quantities?

Looking to place a bulk order? We're here to assist! Simply contact us with your product choices and the quantities you need, and we'll promptly respond to your request.

Collaborations

Uniting with Talented Artists

Carmel is always thrilled to partner with artists and professionals from various styles and backgrounds. Our Montreal North headquarters houses an exclusive art studio, regularly hosting visiting artists.

Collaborations

Taking Mixed-Media Art to New Heights

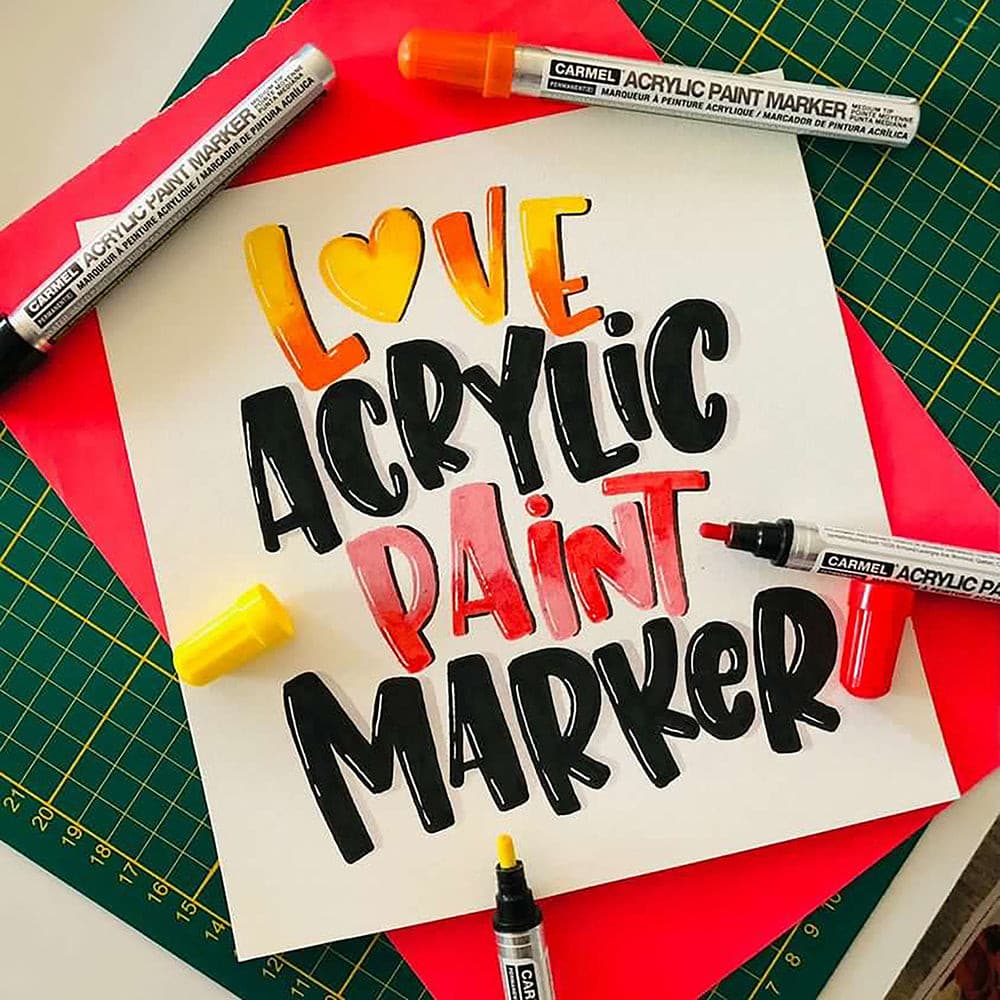

Our marker product line excels in mixed-media arts, especially when used on unconventional surfaces like metal, stone, brick, ceramic, and textiles.

Carmel Markers are the best thing I've gotten my hands on.

Adi Spiegelman (@adi.spiegelman)

Carmel Acrylic Paint Markers are really amazing!

Viviana Valdez of Team ZHC (@itsvivee)

The Facilities

Paint Manufacturing Department

The Paint Manufacturing Department dreams up unique paint formulas for every possible craftsperson in the world.

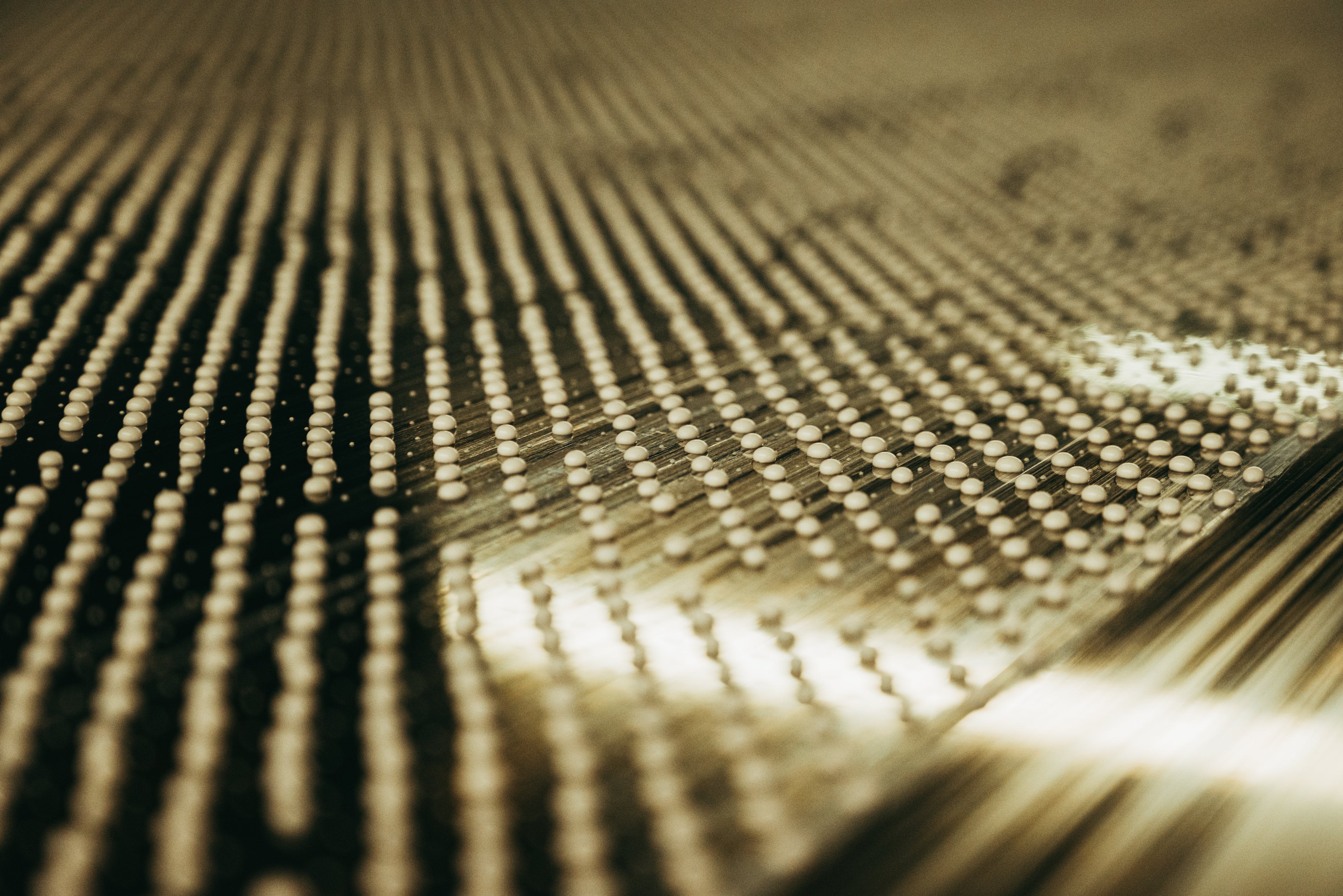

Wax Department

The Wax Department conducts wax extrusion, wax pastillating, and sheet manufacturing. Our products cater to candlemakers, orthodontists, estheticians, dentists, and pedorthists

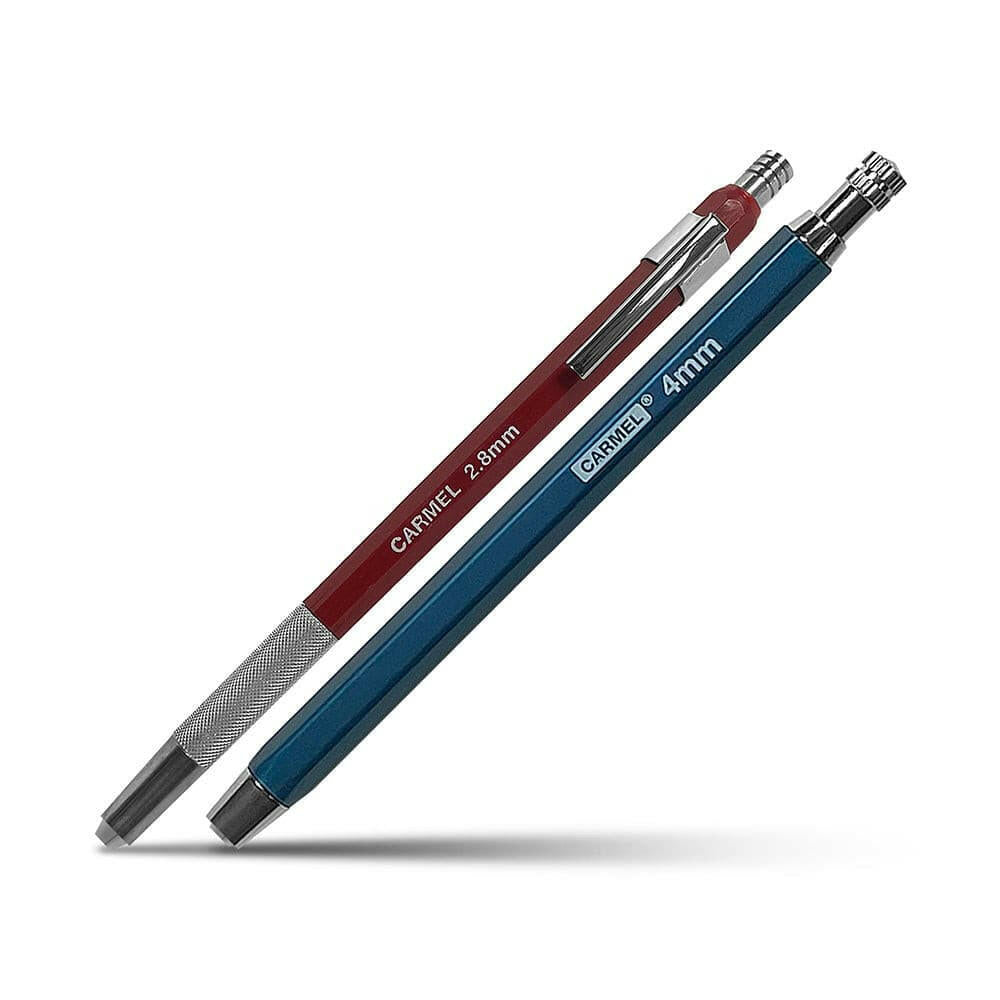

Plastic Molding Department

The Marker Component Manufacturing Department produces plastic marker parts because every writing tool is unique and has a particular purpose.

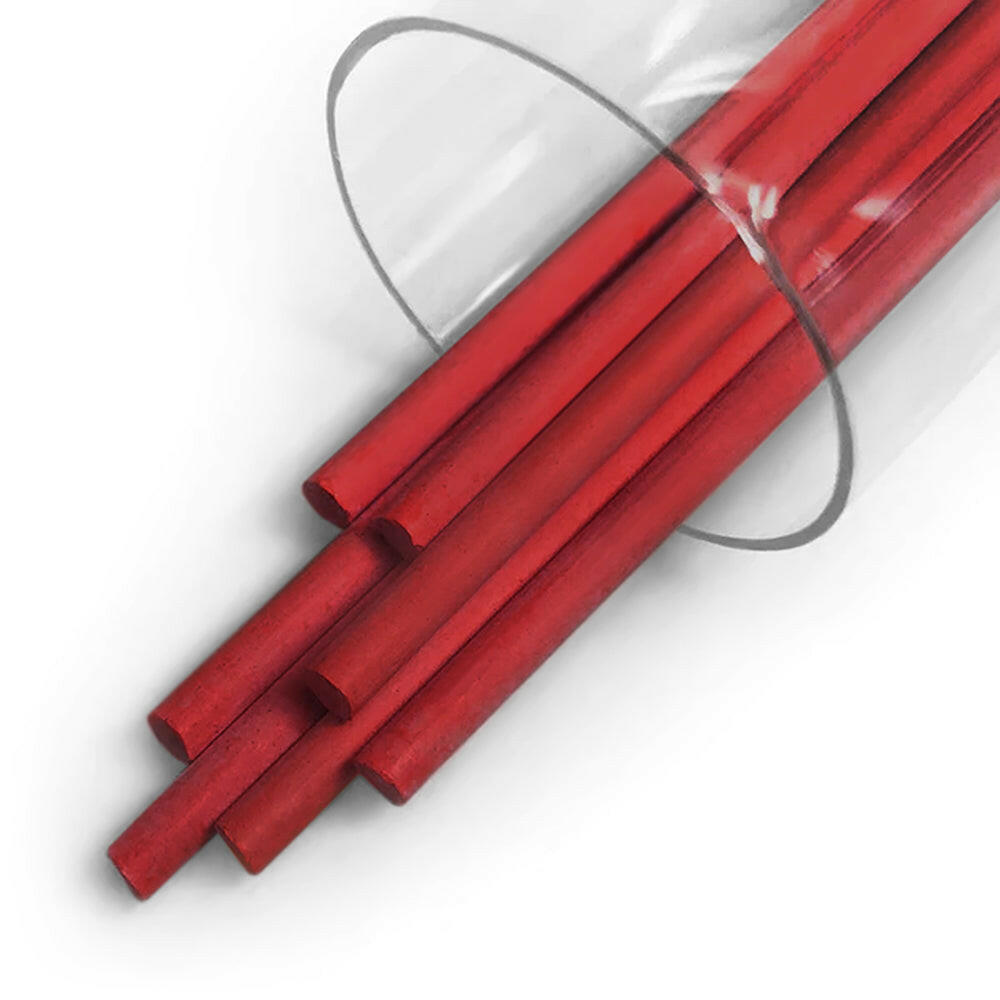

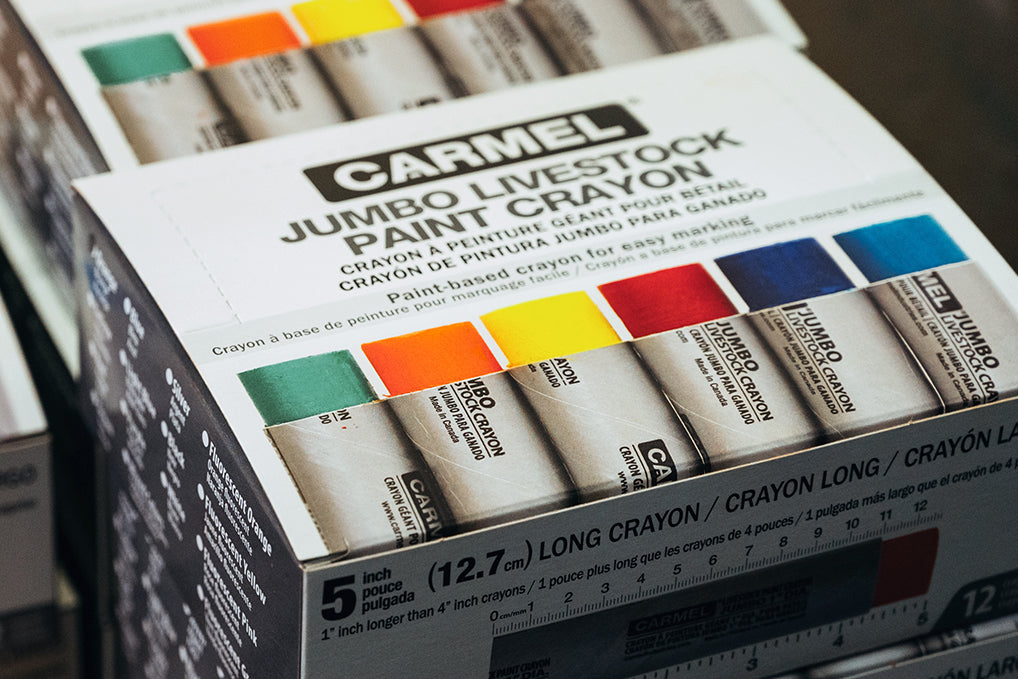

Crayon Manufacturing Department

The Crayon Manufacturing Department specializes in crafting an extensive array of products, including Paint Crayons and Jumbo Livestock Paint Crayons, tailored to cater to the unique needs of a global clientele.